In a world where fast fashion dominates and sustainability is often just a buzzword, Nicolas Schierle is making real change. As the co-founder of Labwear Studios, he’s on a mission to turn the fashion industry upside down, using technology to empower emerging designers and create a more sustainable production model. From the Swiss headquarters to an integrated factory network in Portugal, Labwear Studios shares how its team is transforming fashion into a more sustainable and inclusive landscape. How do we tackle overproduction, and reshape the future of fashion with a democratic, agile approach? Spoiler alert: it’s all about giving power back to the creators.

hube: Labwear Studios has pioneered the integration of technology into the fashion supply chain. How do you see your platform, Labwear_OS, transforming the way independent designers bring their ideas to life, and what impact do you hope it will have on the future of fashion production?

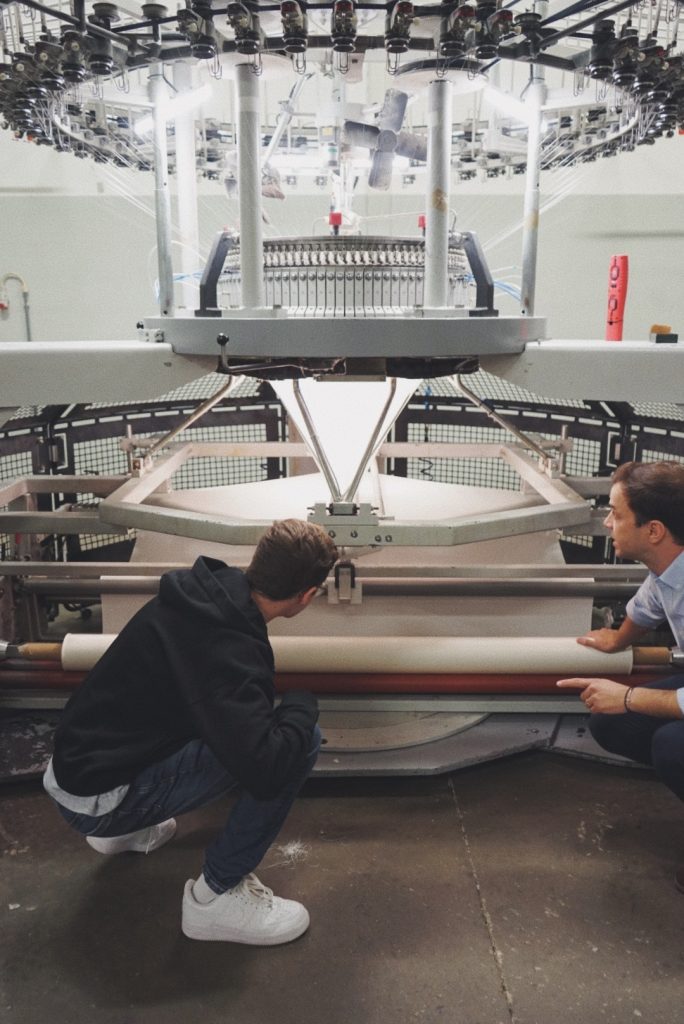

Nicolas Schierle: We started by building our fashion brands. We quickly realised how difficult it was to access good manufacturers. The big players like Balenciaga or Off-White have their preferred factories, and those manufacturers are focused on massive quantities. Even something that seems simple, like producing a t-shirt, involves five different factories – one for the yarns, another for knitting the fabric, a third for dyeing, and so on. It’s overwhelmingly complex, and if you’re a small brand, you’re often not taken seriously.

We wanted to fix that. We saw even big brands struggling with their production, so we built a platform that allows emerging brands to access the same high-end factories, but with much smaller minimum quantities. Before, you’d have needed an order of 500 to even get a foot in the door. Now, we’re giving smaller brands the tools to produce high-quality garments in as few as 50 pieces. It’s a game-changer for the industry.

h: When you started Labwear_OS, was there an organisation that inspired your vision? Or was there a specific moment that pushed you to create this platform?

NS: It wasn’t inspired by anyone in particular. It was more about solving the problems we faced as brand owners. We looked for solutions in the market, but we didn’t find anything that worked for us. So, we decided to build it ourselves, step by step. We did recognise that companies like New Guards Group helped creatives like Virgil Abloh bring his designs to life, we knew that if we could create the right platform, it would make a huge difference for small brands.

h: Your approach to fashion focuses on on-demand production to combat overproduction and waste. Can you walk us through how this system works, and how it addresses some of the most pressing challenges in the traditional fashion supply chain?

NS: The fashion industry is built on mass production, where brands race to lower costs by producing more. This leads to more overproduction and more waste. Think about how many t-shirts are sitting in landfills because they were produced too cheaply and in excess. Traditional supply chains are rigid; brands have to plan their orders a year in advance, and then they’re stuck with whatever they guessed would sell.

With Labwear_OS, we’re breaking that cycle. We’ve reduced minimum order quantities and shortened lead times to four to eight weeks. This allows brands to produce smaller batches, restock quickly based on actual demand, and avoid the pitfalls of overproduction. It’s an agile approach that aligns better with today’s fast-moving trends.

h: Labwear Studios is more than just a manufacturer – it’s a community for creators. How does nurturing this sense of community influence your business model, and what role does it play in your overall vision for the future of fashion?

NS: For us, community is everything. The feedback we get from our community directly influences our business decisions. Our vision is to equip the fashion designers of tomorrow with the tools they need to succeed. We believe the future of fashion will be shaped by emerging designers, not the big houses that currently dominate the industry. Our job is to give these designers the resources they need, levelling the playing field so creativity, not money, is what drives success. It’s about democratising fashion.

h: You emphasise empowering young and ambitious designers through access to high-quality production and resources. How do you ensure that Labwear Studios remains accessible and supportive to up-and-coming designers who are just starting out?

NS: Democratising garment manufacturing is at the core of what we do. Every decision we make comes down to one question: how can we make more resources available? We’re constantly working on digitising the entire workflow from designing garments to managing production while reducing minimum order quantities (MOQs) across all categories – whether it’s T-shirts, denim, or activewear – so that emerging designers can access the same top-tier factories that big brands use. We’ve also got some exciting campaigns in the works to promote new talent, although I can’t share too many details just yet!

h: Sustainability is a core pillar for Labwear Studios, especially with your commitment to localised production and circularity. How do you ensure that these practices are maintained across all your partnerships and operations?

NS: We audit every factory we work with to ensure they meet social requirements, and we integrate our core principles in every aspect of production. One principle that’s crucial for us is the use of monofiber fabrics, which are fully recyclable. It’s a huge issue when garments are labelled ‘sustainable’ but are made from a blend of materials that can’t be recycled. We’re also introducing recycled cotton and new dyeing technologies to our offerings, and integrating ESG tracking tools so our brands can monitor their environmental impact more transparently.

h: As digital fashion and the metaverse become more prevalent, how do you envision Labwear Studios adapting to or integrating with these new virtual spaces? What opportunities do you see in this evolving landscape?

NS: We’re focusing on two key areas: digital sampling and creating a ‘digital twin’ of our entire manufacturing infrastructure. Digital sampling allows us to experiment with new designs without needing to produce anything, saving a lot of resources physically. The digital twin will replicate our physical manufacturing setup, allowing us to provide full transparency to our customers. Imagine being able to virtually tour the factory where your clothes are being made. We see a lot of potential in virtual community meetups and events as well.

h: Looking ahead, what are the next big challenges and opportunities for Labwear Studios? Are there any new technologies or markets you’re particularly excited to explore in the coming years?

NS: Right now, we’re expanding into new product categories – activewear is next, and we’ll be launching that in a few weeks. The demand for activewear is skyrocketing, and we’re excited to explore that space. Beyond that, we’ll be collecting more data to make our manufacturing algorithms even smarter. The goal is to have the most efficient supply network, where designers can choose between the fastest production times, the greenest products, or other priorities – all backed by data. It’s going to be a really exciting journey.

Photography courtesy of the LABWEAR STUDIOS